A Six-Month Saga: Battling the 3D Printer and Developing a DIY Exhaust System

Soon after I started using a 3D printer, I ran into a significant problem.

When printing with ABS material, the printer's glass started to fog up, and a distinct smell of plastic filled the air. My research revealed that ABS resin emits VOCs (Volatile Organic Compounds) during printing.

Opinions on VOC countermeasures are divided; some experts argue they are unnecessary, while others insist they are absolutely essential. However, because I have a pre-existing medical condition, I decided that measures were vital if I were to rely on ABS, which was likely to become my primary material.

A Rash Decision and Endless Trial and Error

I could have easily bought a commercial VOC mitigation device, but I rashly decided to "build my own."

Looking back, this decision marked the beginning of unimaginable struggles. If I had known it would take half a year from design to completion, I would have certainly repurposed a ready-made product. Instead, I naively insisted on a DIY approach, which cost me about six months.

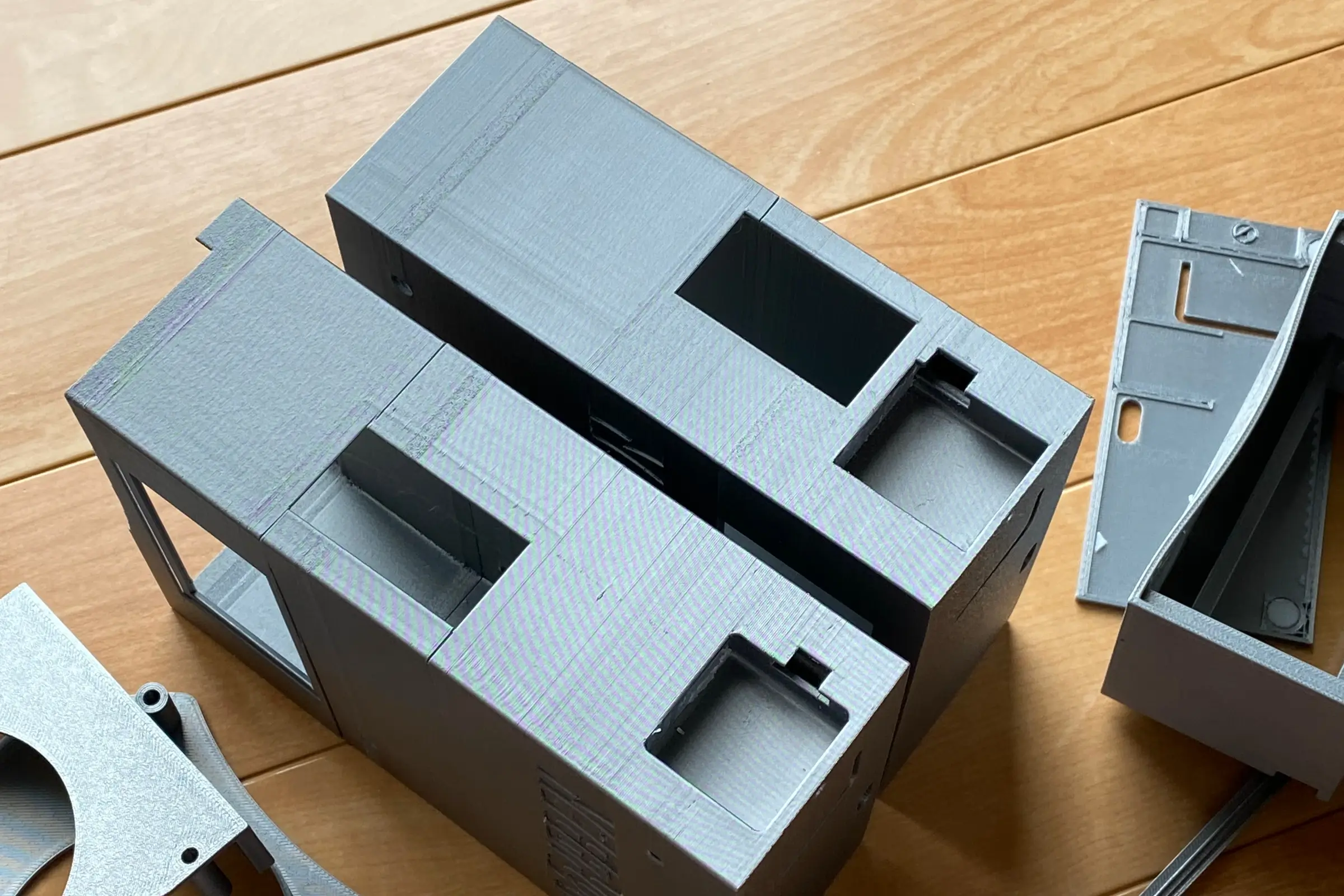

The hardest part was the continuous cycle of prototyping, failure, and redesigning.

The first three months were a period of despair. Every prototype failed, and I repeatedly questioned myself, "What am I doing?" and "Is this a pointless effort?" I was driven by the thought, "It would be easier to just give up," more than once or twice.

Completion and Learning Through Perseverance

However, I told myself that giving up on this DIY project was tantamount to giving up on 3D printing itself. With that resolve, I continued through failures for another three months.

Strangely enough, as I persevered, moments of inspiration began to strike, and my ideas became clearer. Finally, I completed exactly what I had aimed for: a completely original VOC mitigation device.

I wasted about 7 kg of material in total, enduring continuous prototyping and redesigns. Was it necessary to take the risk of building it myself? Now that it's complete, the answer is clear.

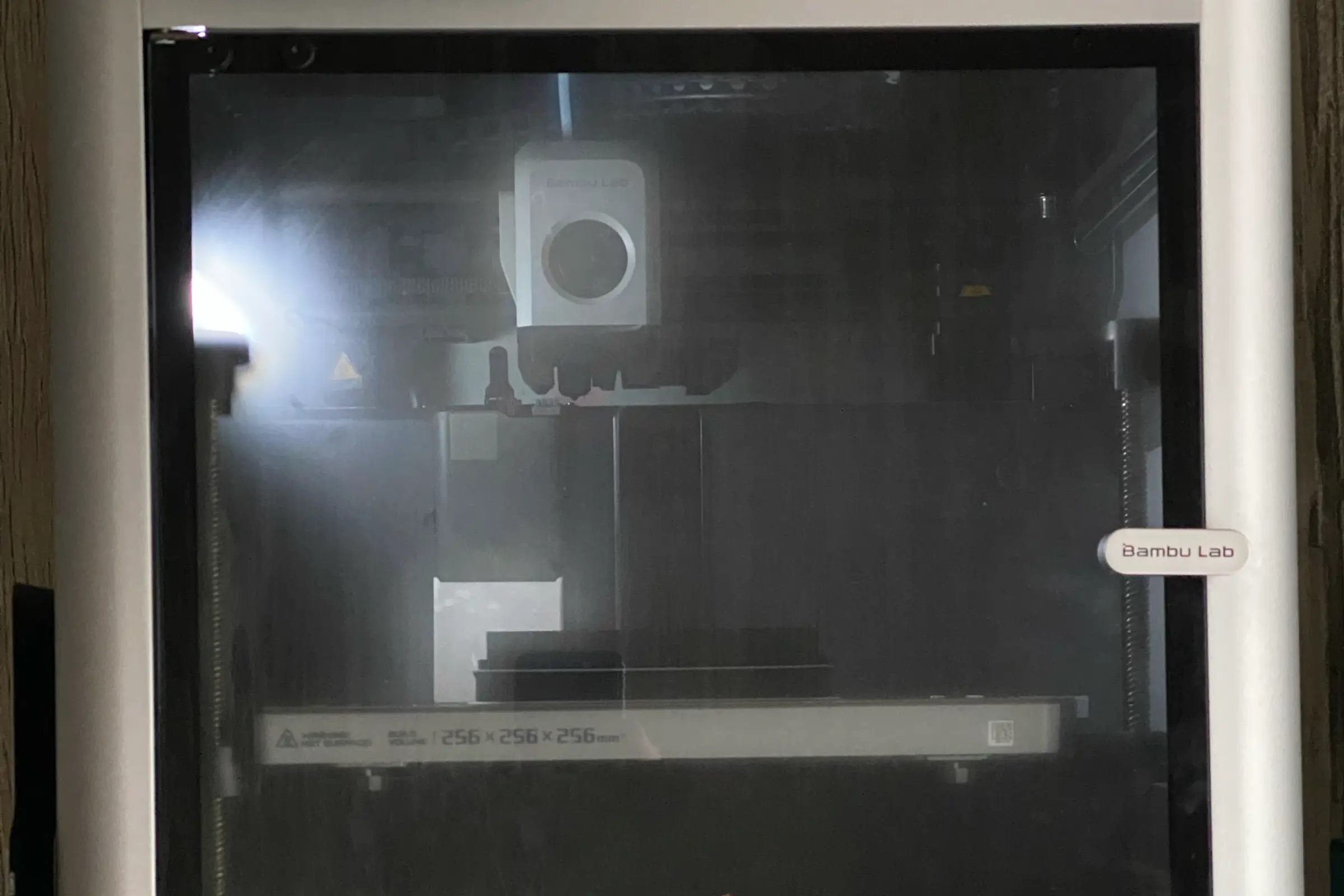

I installed the finished VOC mitigation device on the printer and resumed printing with ABS material about a week ago. The result is perfect; the glass is completely clear, and that unpleasant odor is gone.

Valuable Experience Gained from Failure

This half-year was not wasted.

By completing the DIY exhaust system, I gained a deep understanding of the printer's structure and the properties of ABS material. This experience is a significant asset for my future 3D printing endeavors.

I felt keenly that even if it seemed like a detour, not giving up on doing the minimum required task and seeing it through connects to the future.

This experience gave me "the power to complete things" and "the resilience to face challenges.